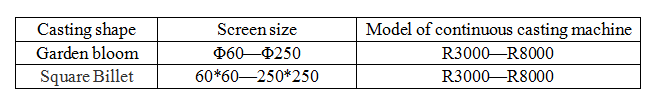

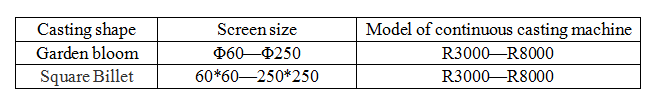

Products Details

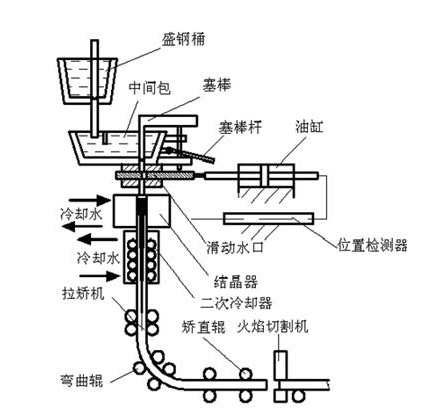

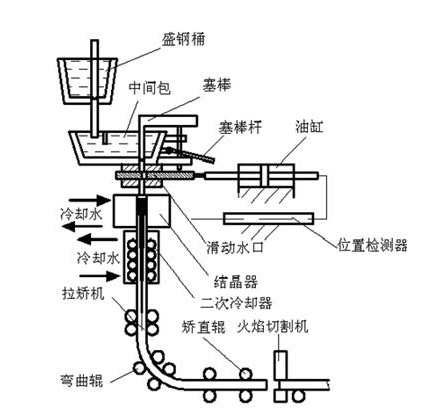

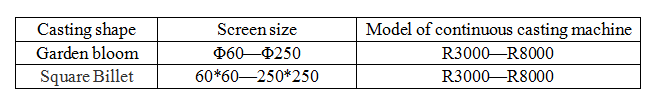

Main process flow is: from molten steel ladle outflow, first into the tundish, then into arc crystallizer, formed in crystallizer slab roller downward movement along the arc, arc movement by water spray cooling, until the complete or partial solidified, then casting to the horizontal tangent point into the machine, then use the flame cutting handlebar slab cutting length, from the horizontal loading.My company's continuous casting machine production of billet mainly have, billet, garden billet.

industrial gearbox,

Compound mixing machine,

electric lead melting furnace,

roller straightener machine,

Automatic heating furnace,

kiln for melting copper,

China Casting Machine,

China Induction Melting Furnace and Melting Furnace,

electric metal melting furnace,

metal smelting furnace,