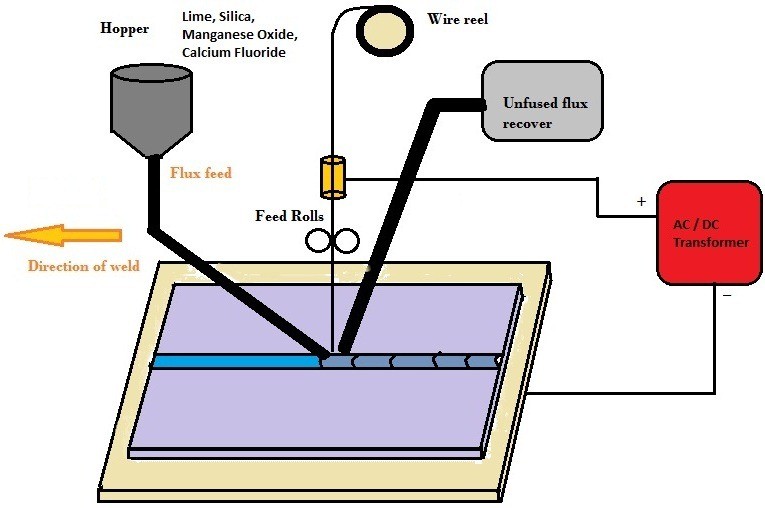

Submerged arc welding (SAW) is a popular welding process that is widely used in diverse industries, such as construction, shipbuilding, and manufacturing. It is a fusion welding technique in which the arc is submerged below a bed of granular flux. This method of welding is typically performed using a consumable solid or tubular electrode, and the weld and arc are protected from atmospheric contamination by a layer of fusible flux.

SAW offers several advantages over other welding methods, making it a preferred choice in many applications. Let's take a closer look at some of the key benefits of SAW.

1. High Welding Velocity

One of the most significant advantages of SAW is its high welding speed. Unlike some other welding techniques, it is capable of producing long, continuous welds in a short amount of time. This makes it ideal for large-scale production, where high volumes of welding are required.

2. Deep Weld Penetration

Another advantage of SAW is its ability to achieve deep weld penetration. The combination of the submerged arc and the flux provides excellent shielding, allowing the arc to penetrate deeply into the workpiece. This results in high-quality welds that are strong and durable.

3. Low Heat Input

SAW generates less heat compared to some other welding methods. This is because the arc is submerged in the flux, which acts as a coolant, and prevents the weld from getting too hot. As a result, there is less distortion in the weld and less overall strain on the workpiece.

4. High Weld Quality

SAW produces high-quality welds that are free of porosity, slag, and other defects. The flux layer protects the arc and weld pool from atmospheric contamination, reducing the risk of weld defects. Additionally, the deep weld penetration produces a strong, reliable weld that is capable of withstanding heavy loads and harsh environments.

5. Versatility

SAW is a versatile process that can be used on a variety of materials, including carbon steel, stainless steel, and other alloys. It is also suitable for welding thick sections of materials, making it suitable for heavy-duty applications.

Conclusion

Submerged arc welding is a widely used welding process that offers several benefits over other techniques. It is fast, produces high-quality welds, and can be used on a variety of materials. Furthermore, it generates less heat, resulting in less distortion and strain on the workpiece. All in all, SAW is an excellent choice for industries that require high-volume, heavy-duty welding.