Products Details

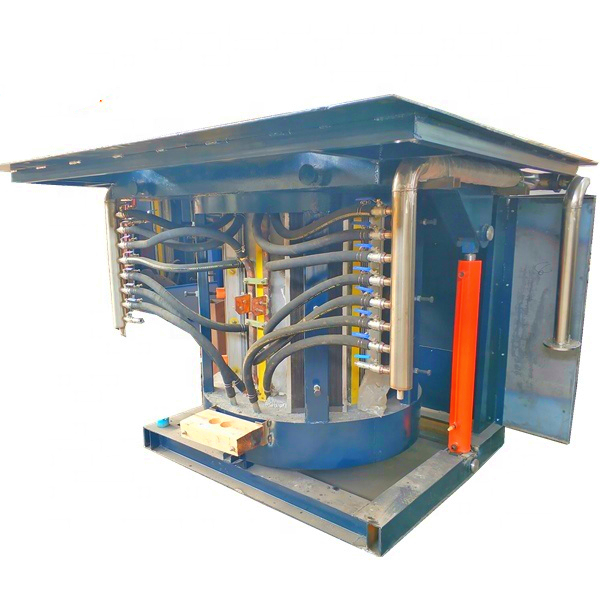

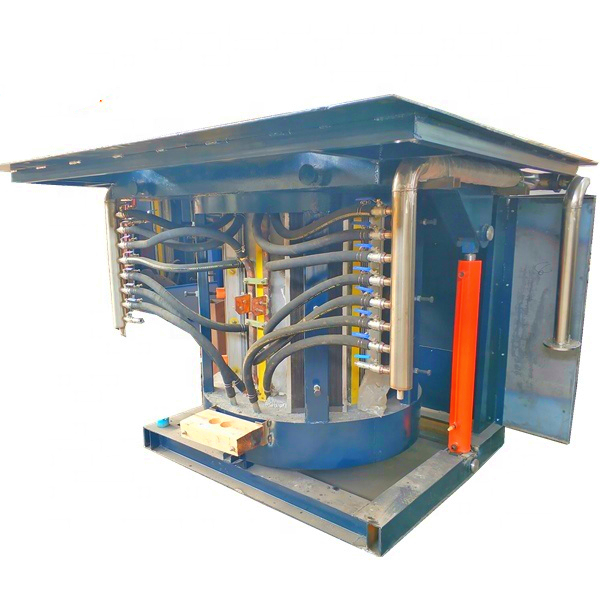

Foundry Intermediate Frequency Furnace is designed and manufactured for the foundry industry scrap metal melting and non-standard medium frequency heating equipment, the use of medium frequency electromagnetic heating principle to quickly melt scrap metal and metal scraps, belongs to the metal remelting category, add trace alloy composition to change the performance index of castings. A, Casting medium frequency furnace profile. 1、Melting metal material: steel, iron, alloy aluminum, alloy copper, stainless steel and other metal materials 2, Melting temperature: steel 1700 degrees: aluminum alloy 850 degrees; copper alloy 1100 degrees; stainless steel 1650 degrees  3, Melting power: depending on the melting time of a single furnace, 160kw - 12000kw; for example, 1 ton of steel scrap casting medium frequency furnace melting power 750Kw / hour. 4, Dumping mode: for steel shell furnace body generally use hydraulic dumping furnace; for aluminum shell furnace, small tonnage furnace body generally use reducer dumping furnace. 5、Power mode: casting medium frequency furnace using medium frequency power supply, power supply structure is divided into parallel resonance and series resonance 6、Furnace lining category: casting medium frequency furnace according to the melting material different furnace lining is divided into: acid furnace lining, alkaline furnace lining and medium-sized furnace lining. For scrap steel melting generally use acidic furnace lining materials; for scrap alloy aluminum melting using alkaline furnace lining. 7, Structure form: casting IF furnace is divided into non-vacuum casting IF furnace and vacuum casting IF furnace two forms. Vacuum casting IF furnace is suitable for special alloy smelting.

3, Melting power: depending on the melting time of a single furnace, 160kw - 12000kw; for example, 1 ton of steel scrap casting medium frequency furnace melting power 750Kw / hour. 4, Dumping mode: for steel shell furnace body generally use hydraulic dumping furnace; for aluminum shell furnace, small tonnage furnace body generally use reducer dumping furnace. 5、Power mode: casting medium frequency furnace using medium frequency power supply, power supply structure is divided into parallel resonance and series resonance 6、Furnace lining category: casting medium frequency furnace according to the melting material different furnace lining is divided into: acid furnace lining, alkaline furnace lining and medium-sized furnace lining. For scrap steel melting generally use acidic furnace lining materials; for scrap alloy aluminum melting using alkaline furnace lining. 7, Structure form: casting IF furnace is divided into non-vacuum casting IF furnace and vacuum casting IF furnace two forms. Vacuum casting IF furnace is suitable for special alloy smelting.  Second, the composition of the casting IF furnace. Aluminum shell casting IF furnace structure: IF power cabinet, capacitor bank, aluminum shell furnace body and water cooling cable, reducer, etc. Steel shell casting IF furnace structure: IF power cabinet, capacitor bank, steel shell furnace body, magnetic yoke and water cooling cable, hydraulic station, leakage furnace alarm, water temperature alarm, etc. Three, casting medium frequency furnace features. 1、Foundry medium frequency furnace heating speed, temperature uniformity, energy saving and environmental protection, less oxidation decarburization 2, casting medium frequency furnace automation degree is high, can realize automatic unmanned operation, improve labor productivity. 3, casting medium frequency furnace heating uniformity, high precision temperature control, through the temperature control system can be precise control of temperature, to ensure that the product repeatability 4、The casting medium frequency furnace is easy to replace the furnace body 5、The casting medium frequency furnace is fully protected with water temperature, water pressure, phase loss, overvoltage, overcurrent, voltage/ current limit, overcurrent start, constant current and buffer start, which makes the equipment start smoothly, protect reliably and quickly, and run stably. 6、The casting medium frequency furnace has low energy consumption, no pollution, and the equipment meets the requirements of environmental protection.

Second, the composition of the casting IF furnace. Aluminum shell casting IF furnace structure: IF power cabinet, capacitor bank, aluminum shell furnace body and water cooling cable, reducer, etc. Steel shell casting IF furnace structure: IF power cabinet, capacitor bank, steel shell furnace body, magnetic yoke and water cooling cable, hydraulic station, leakage furnace alarm, water temperature alarm, etc. Three, casting medium frequency furnace features. 1、Foundry medium frequency furnace heating speed, temperature uniformity, energy saving and environmental protection, less oxidation decarburization 2, casting medium frequency furnace automation degree is high, can realize automatic unmanned operation, improve labor productivity. 3, casting medium frequency furnace heating uniformity, high precision temperature control, through the temperature control system can be precise control of temperature, to ensure that the product repeatability 4、The casting medium frequency furnace is easy to replace the furnace body 5、The casting medium frequency furnace is fully protected with water temperature, water pressure, phase loss, overvoltage, overcurrent, voltage/ current limit, overcurrent start, constant current and buffer start, which makes the equipment start smoothly, protect reliably and quickly, and run stably. 6、The casting medium frequency furnace has low energy consumption, no pollution, and the equipment meets the requirements of environmental protection.

Metal Rolling Machine,

China Turning Lathe,

nickel melting furnace,

high capacity roller mill,

Double Poured Chilled Rolls,

roll body flour mill,

portable roller mill,

China Rolling Mills and Rolling Machine,

rolling mill micrometer,

lead rotary furnace,

3, Melting power: depending on the melting time of a single furnace, 160kw - 12000kw; for example, 1 ton of steel scrap casting medium frequency furnace melting power 750Kw / hour. 4, Dumping mode: for steel shell furnace body generally use hydraulic dumping furnace; for aluminum shell furnace, small tonnage furnace body generally use reducer dumping furnace. 5、Power mode: casting medium frequency furnace using medium frequency power supply, power supply structure is divided into parallel resonance and series resonance 6、Furnace lining category: casting medium frequency furnace according to the melting material different furnace lining is divided into: acid furnace lining, alkaline furnace lining and medium-sized furnace lining. For scrap steel melting generally use acidic furnace lining materials; for scrap alloy aluminum melting using alkaline furnace lining. 7, Structure form: casting IF furnace is divided into non-vacuum casting IF furnace and vacuum casting IF furnace two forms. Vacuum casting IF furnace is suitable for special alloy smelting.

3, Melting power: depending on the melting time of a single furnace, 160kw - 12000kw; for example, 1 ton of steel scrap casting medium frequency furnace melting power 750Kw / hour. 4, Dumping mode: for steel shell furnace body generally use hydraulic dumping furnace; for aluminum shell furnace, small tonnage furnace body generally use reducer dumping furnace. 5、Power mode: casting medium frequency furnace using medium frequency power supply, power supply structure is divided into parallel resonance and series resonance 6、Furnace lining category: casting medium frequency furnace according to the melting material different furnace lining is divided into: acid furnace lining, alkaline furnace lining and medium-sized furnace lining. For scrap steel melting generally use acidic furnace lining materials; for scrap alloy aluminum melting using alkaline furnace lining. 7, Structure form: casting IF furnace is divided into non-vacuum casting IF furnace and vacuum casting IF furnace two forms. Vacuum casting IF furnace is suitable for special alloy smelting.  Second, the composition of the casting IF furnace. Aluminum shell casting IF furnace structure: IF power cabinet, capacitor bank, aluminum shell furnace body and water cooling cable, reducer, etc. Steel shell casting IF furnace structure: IF power cabinet, capacitor bank, steel shell furnace body, magnetic yoke and water cooling cable, hydraulic station, leakage furnace alarm, water temperature alarm, etc. Three, casting medium frequency furnace features. 1、Foundry medium frequency furnace heating speed, temperature uniformity, energy saving and environmental protection, less oxidation decarburization 2, casting medium frequency furnace automation degree is high, can realize automatic unmanned operation, improve labor productivity. 3, casting medium frequency furnace heating uniformity, high precision temperature control, through the temperature control system can be precise control of temperature, to ensure that the product repeatability 4、The casting medium frequency furnace is easy to replace the furnace body 5、The casting medium frequency furnace is fully protected with water temperature, water pressure, phase loss, overvoltage, overcurrent, voltage/ current limit, overcurrent start, constant current and buffer start, which makes the equipment start smoothly, protect reliably and quickly, and run stably. 6、The casting medium frequency furnace has low energy consumption, no pollution, and the equipment meets the requirements of environmental protection.

Second, the composition of the casting IF furnace. Aluminum shell casting IF furnace structure: IF power cabinet, capacitor bank, aluminum shell furnace body and water cooling cable, reducer, etc. Steel shell casting IF furnace structure: IF power cabinet, capacitor bank, steel shell furnace body, magnetic yoke and water cooling cable, hydraulic station, leakage furnace alarm, water temperature alarm, etc. Three, casting medium frequency furnace features. 1、Foundry medium frequency furnace heating speed, temperature uniformity, energy saving and environmental protection, less oxidation decarburization 2, casting medium frequency furnace automation degree is high, can realize automatic unmanned operation, improve labor productivity. 3, casting medium frequency furnace heating uniformity, high precision temperature control, through the temperature control system can be precise control of temperature, to ensure that the product repeatability 4、The casting medium frequency furnace is easy to replace the furnace body 5、The casting medium frequency furnace is fully protected with water temperature, water pressure, phase loss, overvoltage, overcurrent, voltage/ current limit, overcurrent start, constant current and buffer start, which makes the equipment start smoothly, protect reliably and quickly, and run stably. 6、The casting medium frequency furnace has low energy consumption, no pollution, and the equipment meets the requirements of environmental protection.