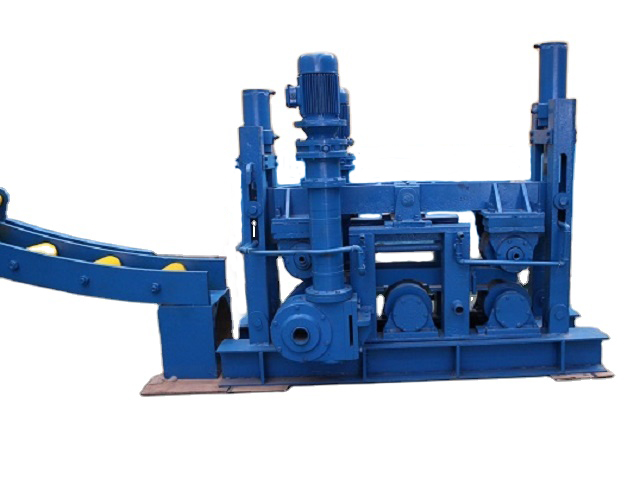

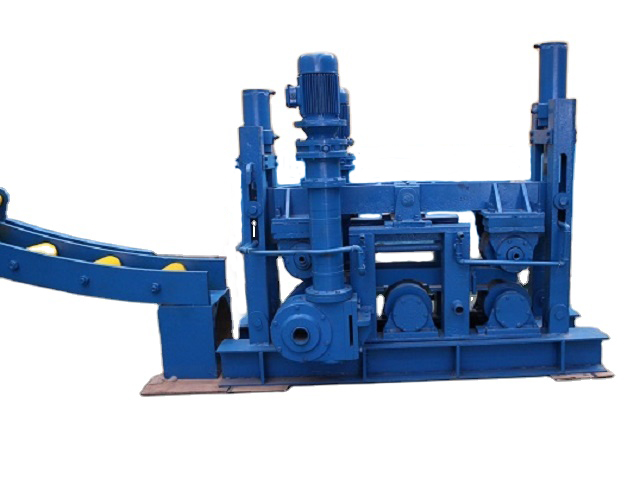

Products Details

The process of continuous casting of high temperature steel into billets with a certain cross-sectional shape and certain size is called continuous steel casting. The equipment required to complete this process is called continuous casting plant. The electromechanical-hydraulic integration of the steel pouring equipment, the continuous casting machine body equipment, the cutting area equipment, the ingot rod collection and conveying equipment constitutes the core part of the continuous steel casting equipment, which is customarily called the continuous casting machine. | Brand | Runxiang | Kiln length | 24m |

| Weight | 5000-90000kg | Smelting process | short process |

| Specification | R3000-R9000 | Rolling temperature | >950℃ |

| Number of rolls | 5 | Motor power | 2.2KW-50KW |

| Process type | Vertical arc | Dimension | 24000mm |

| Processing custom | Yes | Cutting tolerance± | 1mm |

| Application object | Steel mills, rolling mills | Use | Production of billet or garden billet |

| Production capacity | 1-50t/h | Place of origin | Guangxi, China |

Continuous caster production process. The high-temperature steel is continuously poured into a water-cooled copper crystallizer or a group of water-cooled crystallizers, and the steel gradually solidifies into a billet shell along the perimeter of the crystallizer, and then the billet is pulled out by a pulling machine after the steel level rises to a certain height and the shell solidifies to a certain thickness, and the billet is completely solidified by water spray cooling in the secondary cooling zone, and is cut to a fixed size by the cutting device according to the rolling requirements. This process of making high temperature steel directly poured into the billet is called continuous casting. Its emergence has fundamentally changed a century of dominant ingot a out of rolling process. Because of its simplification of the production process, improve the production efficiency and metal yield, save energy consumption so that production costs are greatly reduced, billet quality and other advantages of rapid development. Nowadays, it is almost inevitable to equip continuous casting machine for steel making enterprises, no matter it is long process steel making or short process steel making.  Why choose us? Skilled technology - low noise - stable operation Years of experience in the industry, choose Runxiang machinery, so that you can rest assured production Runxiang continuous casting machine advantages: 1. 1. Complete specifications, support customization. We will recommend the suitable model for you according to your use requirements. 2. Fast delivery, strict testing, the product factory after layers of inspection. 3. Factory direct sales, considerate service. Features. 1. High surface finish of continuous casting machine, stable performance. 2. Quality assurance, use assured. 3. After-sales guarantee, so that you buy continuous casting machine without worries.

Why choose us? Skilled technology - low noise - stable operation Years of experience in the industry, choose Runxiang machinery, so that you can rest assured production Runxiang continuous casting machine advantages: 1. 1. Complete specifications, support customization. We will recommend the suitable model for you according to your use requirements. 2. Fast delivery, strict testing, the product factory after layers of inspection. 3. Factory direct sales, considerate service. Features. 1. High surface finish of continuous casting machine, stable performance. 2. Quality assurance, use assured. 3. After-sales guarantee, so that you buy continuous casting machine without worries.

Two-Roll Mill,

metal melting furnace,

sheet straightening machine,

Steel rolling mill column,

Aluminum Shell Furnace,

Induction Furnace Diagram,

Customized melting equipment,

Automatic Cooling Bed For Steel Rolling Mill,

gas gold melting furnace,

China Machine Lathe Bed and Rolling Mill Housing,

Why choose us? Skilled technology - low noise - stable operation Years of experience in the industry, choose Runxiang machinery, so that you can rest assured production Runxiang continuous casting machine advantages: 1. 1. Complete specifications, support customization. We will recommend the suitable model for you according to your use requirements. 2. Fast delivery, strict testing, the product factory after layers of inspection. 3. Factory direct sales, considerate service. Features. 1. High surface finish of continuous casting machine, stable performance. 2. Quality assurance, use assured. 3. After-sales guarantee, so that you buy continuous casting machine without worries.

Why choose us? Skilled technology - low noise - stable operation Years of experience in the industry, choose Runxiang machinery, so that you can rest assured production Runxiang continuous casting machine advantages: 1. 1. Complete specifications, support customization. We will recommend the suitable model for you according to your use requirements. 2. Fast delivery, strict testing, the product factory after layers of inspection. 3. Factory direct sales, considerate service. Features. 1. High surface finish of continuous casting machine, stable performance. 2. Quality assurance, use assured. 3. After-sales guarantee, so that you buy continuous casting machine without worries.