Products Details

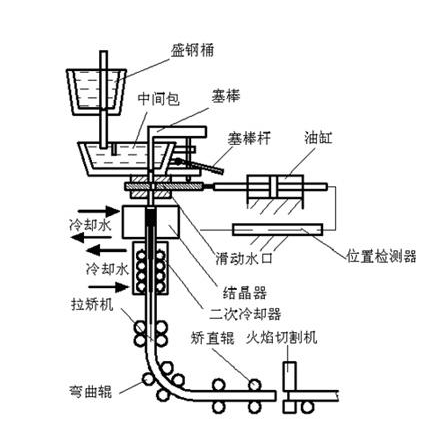

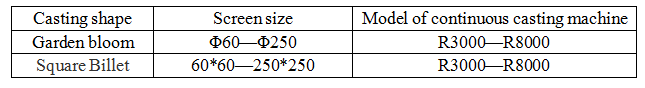

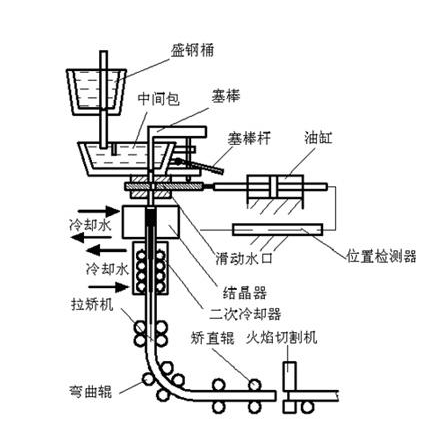

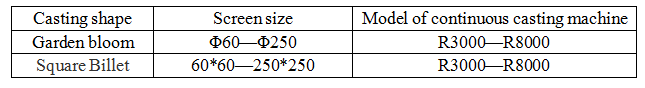

Main process flow is: from molten steel ladle outflow, first into the tundish, then into arc crystallizer, formed in crystallizer slab roller downward movement along the arc, arc movement by water spray cooling, until the complete or partial solidified, then casting to the horizontal tangent point into the machine, then use the flame cutting handlebar slab cutting length, from the horizontal loading. My company's continuous casting machine production of billet mainly have, billet, garden billet.

um of 8; for high speed steel and tool steel, take a minimum of 10; for carbon steel and low alloy steel, take 6. The section size of billet should be determined according to the need of rolling and the compression ratio during rolling. The capacity of the furnace and the capacity of the casting machine should also be considered. It is generally equipped with large section and multi - flow continuous casting machine for large steelmaking furnaces. The rolling compression is preferable 6 ~ 10. For stainless steel and heat resistant steel, take a minim

um of 8; for high speed steel and tool steel, take a minimum of 10; for carbon steel and low alloy steel, take 6. The section size of billet should be determined according to the need of rolling and the compression ratio during rolling. The capacity of the furnace and the capacity of the casting machine should also be considered. It is generally equipped with large section and multi - flow continuous casting machine for large steelmaking furnaces. The rolling compression is preferable 6 ~ 10. For stainless steel and heat resistant steel, take a minim

Copper Melting Induction Furnace,

Non-stop casting equipment,

Flying Shears For Bar Rolling,

Hydraulic powered shearing machine,

Lift Table,

Medium Section Mills,

reversing cold mill,

foundry melting furnaces,

Strip Casting,

China Stainless Steel Coil and Stainless Steel Strip,

um of 8; for high speed steel and tool steel, take a minimum of 10; for carbon steel and low alloy steel, take 6. The section size of billet should be determined according to the need of rolling and the compression ratio during rolling. The capacity of the furnace and the capacity of the casting machine should also be considered. It is generally equipped with large section and multi - flow continuous casting machine for large steelmaking furnaces. The rolling compression is preferable 6 ~ 10. For stainless steel and heat resistant steel, take a minim

um of 8; for high speed steel and tool steel, take a minimum of 10; for carbon steel and low alloy steel, take 6. The section size of billet should be determined according to the need of rolling and the compression ratio during rolling. The capacity of the furnace and the capacity of the casting machine should also be considered. It is generally equipped with large section and multi - flow continuous casting machine for large steelmaking furnaces. The rolling compression is preferable 6 ~ 10. For stainless steel and heat resistant steel, take a minim