| Place of Origin | Guangxi, China | Warranty | 1 Year |

| Brand Name | RUNXIANG | Key Selling Points | High Productivity |

| Condition | New | Applicable Industries | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Energy & Mining |

| Machine Type | English wheel | Product name | Flywheel |

| Marketing Type | New Product 2023 | Material | iron |

| Warranty of core components | 1 Year | Size | custom made |

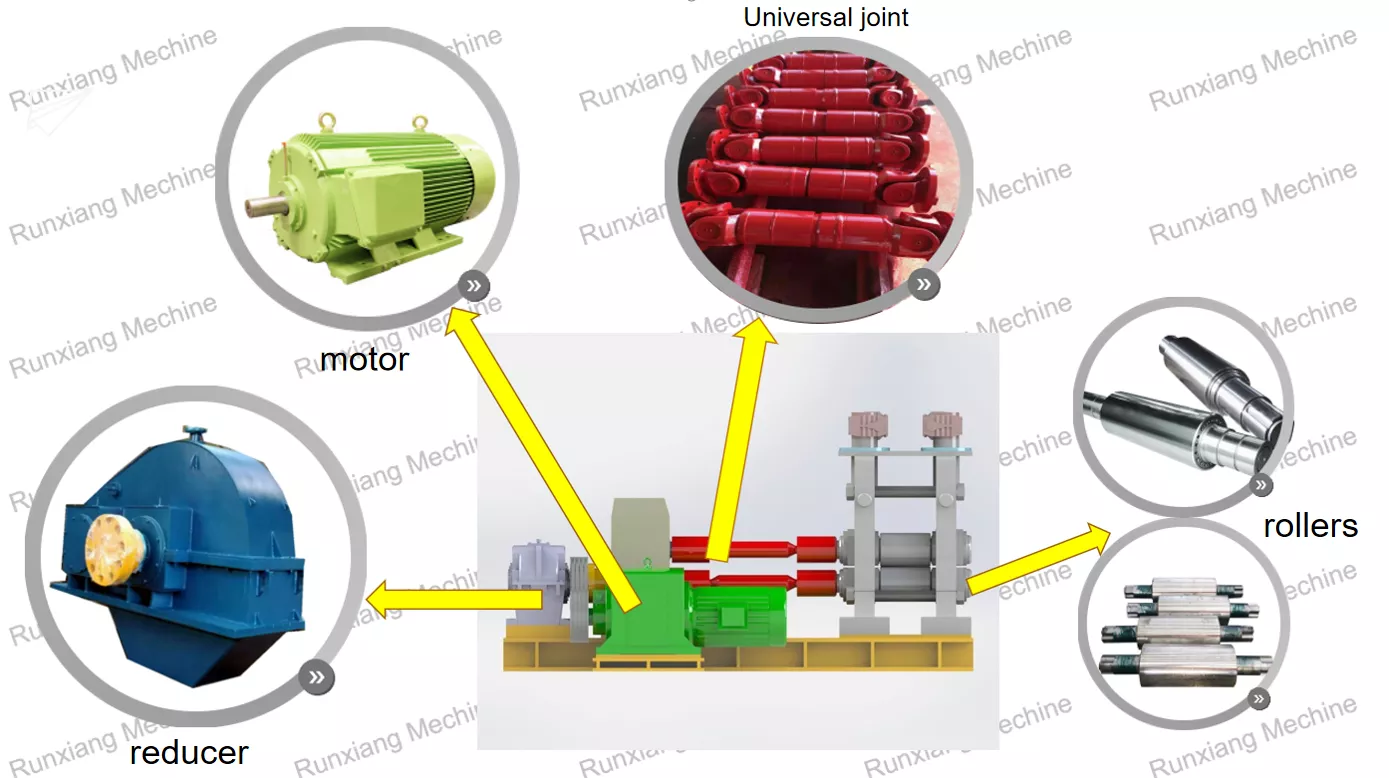

| Core Components | Bearing, Gearbox, Motor, Gear | Color | custom made |

Scope of application (1) rolling time,gap time; (2) rolls are not reversible. Main motor: the equipment that provides power for the rotation of the rolls Transmission mechanism: usually consists of components such as reducer, gear holder, connecting shaft and shaft coupling Work machine seat (1) frame: in its window to install the bearings of the rolls (2) mill roll: the rolled parts are rolled in it (compression deformation) (3) Roll bearings: for the support and positioning of the rolls (4) roll adjustment device and the upper roll balancing device: the former is used to adjust the distance between the rolls, the latter is used to remove the gap between the upper bearing seat and the press down system (5) guide device: used to make the rolling mill rolls in accordance with the specified position, direction and state of accurate access to the hole type (6) rail seat (footplate) frame mounted on the rail seat, rail seat fixed in the foundation Different types of rolling mills, working machine seat components are generally consistent.

Scope of application (1) rolling time,gap time; (2) rolls are not reversible. Main motor: the equipment that provides power for the rotation of the rolls Transmission mechanism: usually consists of components such as reducer, gear holder, connecting shaft and shaft coupling Work machine seat (1) frame: in its window to install the bearings of the rolls (2) mill roll: the rolled parts are rolled in it (compression deformation) (3) Roll bearings: for the support and positioning of the rolls (4) roll adjustment device and the upper roll balancing device: the former is used to adjust the distance between the rolls, the latter is used to remove the gap between the upper bearing seat and the press down system (5) guide device: used to make the rolling mill rolls in accordance with the specified position, direction and state of accurate access to the hole type (6) rail seat (footplate) frame mounted on the rail seat, rail seat fixed in the foundation Different types of rolling mills, working machine seat components are generally consistent.