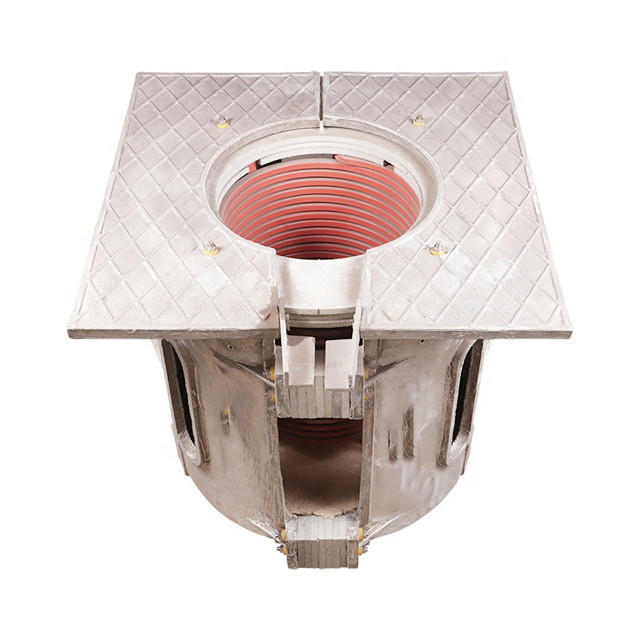

| Product Name | Medium frequency aluminum shell furnace | Heating method | Electricity |

| Brand | Runxiang | Whether energy-saving | yes |

| Processing custom | Yes | Smelting process | Electromagnetic induction |

| Color | Silver | Applicable site | Factory, plant, etc. |

| Melting material | Scrap steel | Use | Melting of metals and precious metals |

Medium frequency furnace is a kind of power supply device that transforms industrial frequency 50HZ alternating current into medium frequency (more than 300HZ to 1000HZ), turns three-phase industrial frequency alternating current into direct current after rectification, and then turns direct current into adjustable medium frequency current, supplies medium frequency alternating current flowing in the capacitor and induction coil, produces high density magnetic lines in the induction coil, and cuts the metal material held in the induction coil, and produces a large eddy current in the This produces a high density of magnetic lines of force in the induction loop and cuts through the metal material held in the induction loop, creating a large eddy current in the metal material.

Product features:

1. High degree of automation, fully automatic and unmanned operation can be realized to improve labor productivity.

2. Uniform heating, to ensure the heating workpiece core table temperature difference is small, through the temperature control system can be precise control of temperature, to ensure the product repeatability.

3. According to the different sizes of the processing workpiece, different specifications of the induction furnace body need to be configured. Each furnace body is designed with water and electricity quick-change connector to make the furnace body easy and fast to replace.

4. High heating efficiency, compared with other heating methods, medium frequency aluminum shell furnace effectively reduces energy consumption, high labor productivity, no pollution, equipment in line with environmental requirements.

Medium frequency aluminum shell furnace can solve the 3 major problems.

1. Traditional forging, sparks everywhere - equipment forging, safe and trouble-free.

2. Metal embryo, the temperature is not enough - temperature up to standard, uniform heating.

3. Can not eliminate, embryo defects - precision quality, automatic processing.

Product real shot

Guangxi Runxiang Machinery Equipment Manufacturing Co., Ltd. was established in May 2021. It is a national high-tech enterprise specializing in R&D, manufacturing, sales and service of steel rolling production line equipment. At present, it has production supporting processes such as steelmaking, cast steel, heat treatment, mechanical processing, and surfacing welding, forming an integrated industrial chain of smelting, casting, metal heat treatment, and mechanical processing.