| Place of Origin | China | Power | 500-10000 |

| Brand Name | Runxiang | Dimension(L*W*H) | 1.7*1.3*1.5 |

| Type | Hot Rolling Mill | Warranty | 1 Year |

| Condition | New | Key Selling Points | High Productivity |

| Machinery Test Report | Provided | Applicable Industries | Building Material Shops, Manufacturing Plant, Retail, Construction works |

| Marketing Type | New Product 2023 | Product name | Hot Rolling Mill |

| Warranty of core components | 1 Year | Color | Any |

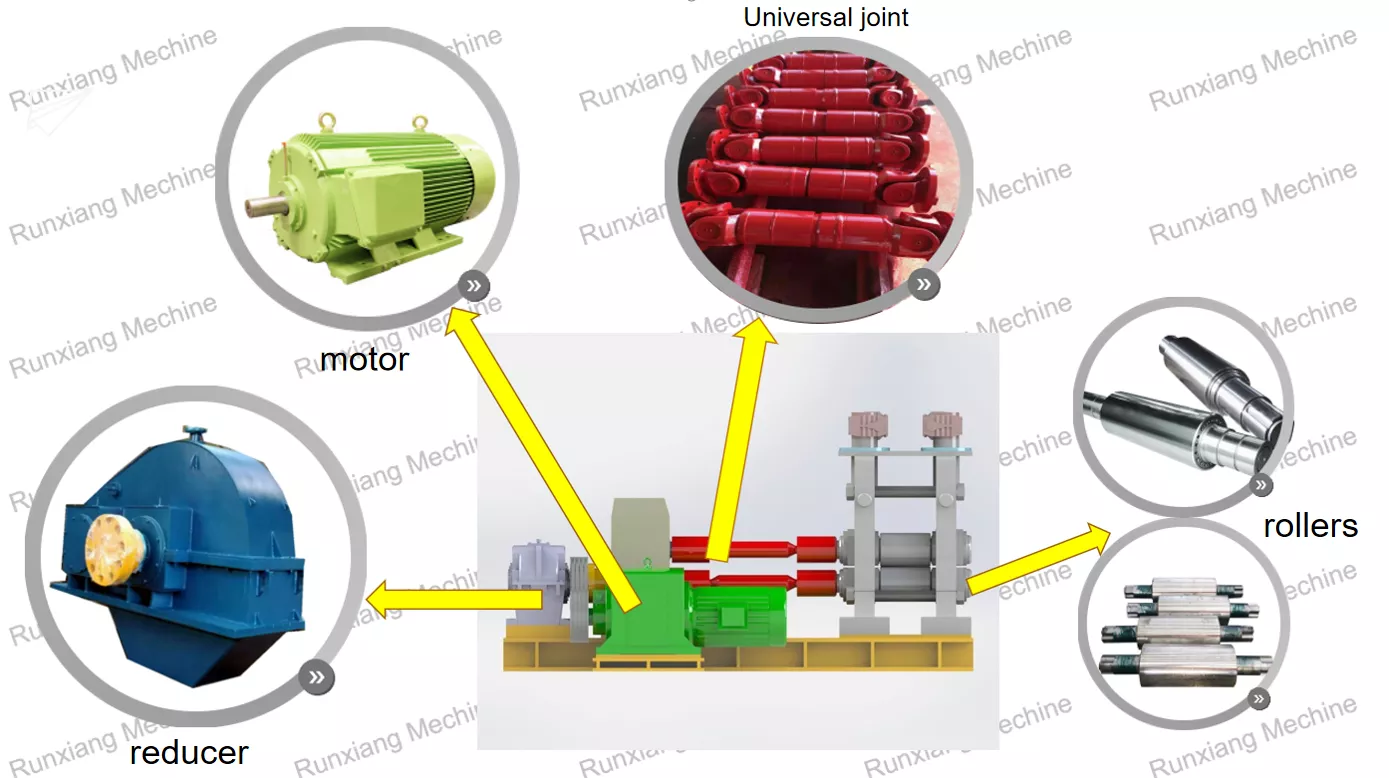

| Core Components | Bearing, Gearbox, Motor, Gear | Standard | Customization |

| Voltage | 380V/6000V | Raw materia | Continuous casting billet |

1, the naming of the rolling mill

Rolling varieties, mill type and nominal size to name. "Nominal size" principle for profile mills, is named after the diameter of the gear seat herringbone gear knuckle; primary rolling mill is named after the nominal diameter of the roll; strip mill is named after the length of the working roll body; pipe mill to produce the largest diameter to name. Sometimes the name of the inventor of the mill to name (such as Senjimir mill).

According to the production of product varieties, specifications, quality and production requirements to select the finished or semi-finished mill type and size, and equipped with the necessary auxiliary, lifting and transport and ancillary equipment, and then according to the requirements of various factors to finally balance the selected.

3, rolling mill power facilities

In 1590, Britain began to use water turbines to drag the rollers, until 1790 there are water turbines with stone flywheel to drag the four-roller steel mill. 1798 Britain began to use steam engine to drag the mill. Modern mills are DC or AC motor drag, there is a single drag, but also through the gears into a group drag.

4, the development of rolling mills

The trend of modern rolling mill development is continuous, automated, professional, high product quality, low consumption. 60s since the mill in the design, research and manufacturing has made great progress, so that hot and cold strip mill, thick plate mill, high-speed wire rod mill, H section mill and even rolling tube unit performance more perfect, and the emergence of rolling speed of up to 115 meters per second wire rod mill, full continuous strip Cold rolling mills, 5500mm wide plate mills and continuous H-beam mills and a series of advanced equipment. The raw material unit weight for rolling mills increases, hydraulic AGC, plate shape control, electronic computer program control and testing means are becoming more and more perfect, and rolling varieties are expanding. Some apply to continuous casting, control rolling and other new rolling methods, as well as to adapt to new product quality requirements and improve the economic efficiency of a variety of special structure of the mill are in development.