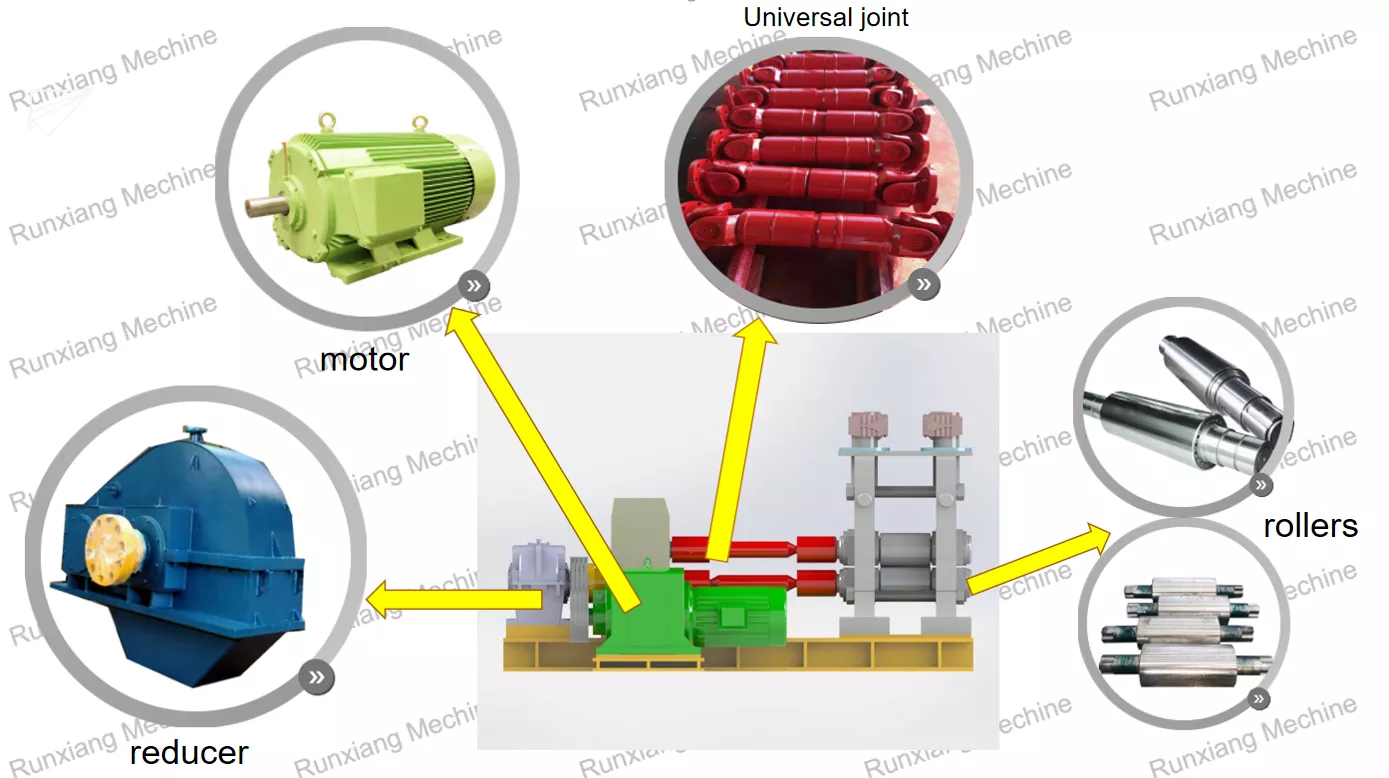

| Place Of Origin | Guangxi, China | Core Components | Engine, Gearbox, Motor, Gear |

| Brand Name | Runxiang | Key Selling Points | High Productivity |

| Condition | New | Applicable Industries | Building Material Shops, Food & Beverage Factory, Home Use, Energy & Mining |

| Machine Type | Wire Mesh Making Machines | Color | Customization |

| Marketing Type | New Product 2023 | Product Name | Hot Rolling Mill |

| Warranty Of Core Components | 1 Year | Standard | Customization |

Roll performance and quality generally depends on its chemical composition and manufacturing methods and can be assessed by its organization, physical and mechanical properties and the type of residual stresses present inside the roll (see Roll Inspection). Roll in the use of rolling mills depends not only on the roll material and its metallurgical quality, but also with the use of conditions, roll design, operation and maintenance. Different types of rolling mill roll conditions vary greatly, resulting in differences in the factors are: (1) mill conditions. Such as mill type, mill and roll design, hole design, water cooling conditions and bearing type; (2) rolling conditions such as rolling material varieties, specifications and its deformation resistance, the pressure system and temperature regime, yield requirements and operation; (3) the quality of the product and surface quality requirements, etc.. Note: composite roll neck material according to the strength requirements to choose. Therefore, different types of mills and the same type and use of different conditions of the mill, the roll performance requirements are not the same, such as billet and slab mill rolls to have good torsional and bending strength, toughness, bite into, resistance to thermal cracking and thermal shock, as well as wear resistance; and tropical finishing mill stand requires high hardness, indentation resistance, wear resistance, resistance to spalling and heat cracking properties of the roll surface. Figure out the conditions of use of the rolls and the failure of the rolls used in the same type of mill, to understand the current performance of various roll materials and manufacturing processes, in order to more correctly develop the technical conditions of the mill with rolls and the choice of suitable and economic roll materials. The most commonly used to evaluate the performance of the rolls in the mill are: (1) rolling 1t rolling material consumed by the weight of the roll (kg) (referred to as roll consumption), with kg / t; (2) each unit of roll diameter to reduce the weight of the rolled material, with t / mm. With the modernization of the mill, the in-depth study of the use of roll failure and roll material and manufacturing process improvements, the average roll consumption in industrial development countries has been reduced to less than 1kg / t.

Roll performance and quality generally depends on its chemical composition and manufacturing methods and can be assessed by its organization, physical and mechanical properties and the type of residual stresses present inside the roll (see Roll Inspection). Roll in the use of rolling mills depends not only on the roll material and its metallurgical quality, but also with the use of conditions, roll design, operation and maintenance. Different types of rolling mill roll conditions vary greatly, resulting in differences in the factors are: (1) mill conditions. Such as mill type, mill and roll design, hole design, water cooling conditions and bearing type; (2) rolling conditions such as rolling material varieties, specifications and its deformation resistance, the pressure system and temperature regime, yield requirements and operation; (3) the quality of the product and surface quality requirements, etc.. Note: composite roll neck material according to the strength requirements to choose. Therefore, different types of mills and the same type and use of different conditions of the mill, the roll performance requirements are not the same, such as billet and slab mill rolls to have good torsional and bending strength, toughness, bite into, resistance to thermal cracking and thermal shock, as well as wear resistance; and tropical finishing mill stand requires high hardness, indentation resistance, wear resistance, resistance to spalling and heat cracking properties of the roll surface. Figure out the conditions of use of the rolls and the failure of the rolls used in the same type of mill, to understand the current performance of various roll materials and manufacturing processes, in order to more correctly develop the technical conditions of the mill with rolls and the choice of suitable and economic roll materials. The most commonly used to evaluate the performance of the rolls in the mill are: (1) rolling 1t rolling material consumed by the weight of the roll (kg) (referred to as roll consumption), with kg / t; (2) each unit of roll diameter to reduce the weight of the rolled material, with t / mm. With the modernization of the mill, the in-depth study of the use of roll failure and roll material and manufacturing process improvements, the average roll consumption in industrial development countries has been reduced to less than 1kg / t.